No... I don't think one has been made?

And after reading everything about beach scoops from everyone... I don't think one will ever be made!

But, I believe two or three "styles" would cover 90% of everyone's need for their "Perfect" scoop.

I have the pencil and paper out again, I'm starting to design another "Ti".

You do remember the first one?...

The next one will be a "shorter" version... The handle will be about 6 inches shorter...

The scoop head will be about 2 inches shorter... and the width will be about 1 1/2 inch shorter.

Why all the "shorter"?

Well... after I finished the first one, my hunting partner asked, "Where's mind!".

My "hunting partner" has been with me for over 40 years now...

and she's meaner than a striped snake, I call her "wife"(most of the time)...

and she's shorter!

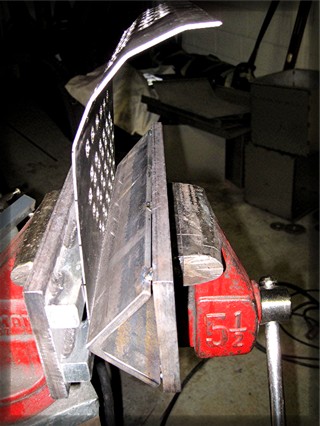

The scoop head on "Ti" is 12" long, 7 3/4" wide, and 6 1/2" high(back).

It weighs 2.94 pounds. The scoop is 4 foot high with the handle held vertical.

Some modifications on the new one will be a scoop head around 10" long, 6 1/2" wide, with the top part extended more to the front and the height about 6 1/2" high. The handle will have less curve.

I have an idea about knowing which way the head is turned without even looking for a mark or line on the top part of the handle... we'll see if it works?

The scoop will be made as light as possible and a target weight near 2 pounds. Even titanium has a strength limit, we'll see if I can find it in this design? The "nose" of the scoop head may come more to point? This should keep it from wanting to turn side-to-side as it digs into the sand? The handle maybe on the outside of the head to keep the small stuff from "hiding"? All holes maybe around 7/16"?

I'm hoping the only thing "short" on this scoop will be the user, if it is...

it'll be as tuff as nails!

And after reading everything about beach scoops from everyone... I don't think one will ever be made!

But, I believe two or three "styles" would cover 90% of everyone's need for their "Perfect" scoop.

I have the pencil and paper out again, I'm starting to design another "Ti".

You do remember the first one?...

The next one will be a "shorter" version... The handle will be about 6 inches shorter...

The scoop head will be about 2 inches shorter... and the width will be about 1 1/2 inch shorter.

Why all the "shorter"?

Well... after I finished the first one, my hunting partner asked, "Where's mind!".

My "hunting partner" has been with me for over 40 years now...

and she's meaner than a striped snake, I call her "wife"(most of the time)...

and she's shorter!

The scoop head on "Ti" is 12" long, 7 3/4" wide, and 6 1/2" high(back).

It weighs 2.94 pounds. The scoop is 4 foot high with the handle held vertical.

Some modifications on the new one will be a scoop head around 10" long, 6 1/2" wide, with the top part extended more to the front and the height about 6 1/2" high. The handle will have less curve.

I have an idea about knowing which way the head is turned without even looking for a mark or line on the top part of the handle... we'll see if it works?

The scoop will be made as light as possible and a target weight near 2 pounds. Even titanium has a strength limit, we'll see if I can find it in this design? The "nose" of the scoop head may come more to point? This should keep it from wanting to turn side-to-side as it digs into the sand? The handle maybe on the outside of the head to keep the small stuff from "hiding"? All holes maybe around 7/16"?

I'm hoping the only thing "short" on this scoop will be the user, if it is...

it'll be as tuff as nails!

7/16...So Right!! I am waiting for new contacts that are supposed to allow me to see the screen better. Or...maybe it's just old age and it was late at night and I should have been in bed instead of reading the forum. Only 3 drill bits and only the larger one was sharpened?? It is tempting. Might be a good winter project. If you like you new one and were willing to share the template, I'd do the holes and then try to find somebody to bend it for me. My neighbor is a good welder and I have a Miller Synchrowave 250, water cooled. Bet the dang rod is expensive but you don't need much. I'll be watching...Jim

7/16...So Right!! I am waiting for new contacts that are supposed to allow me to see the screen better. Or...maybe it's just old age and it was late at night and I should have been in bed instead of reading the forum. Only 3 drill bits and only the larger one was sharpened?? It is tempting. Might be a good winter project. If you like you new one and were willing to share the template, I'd do the holes and then try to find somebody to bend it for me. My neighbor is a good welder and I have a Miller Synchrowave 250, water cooled. Bet the dang rod is expensive but you don't need much. I'll be watching...Jim